Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

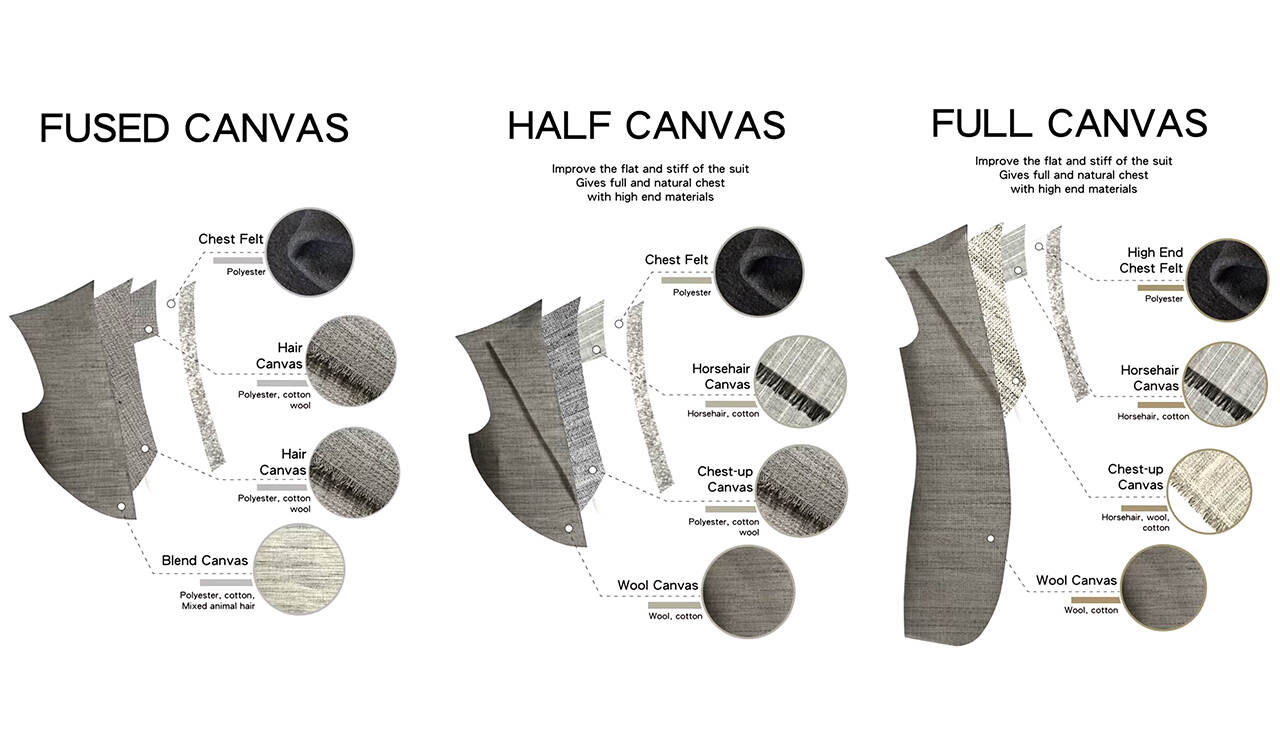

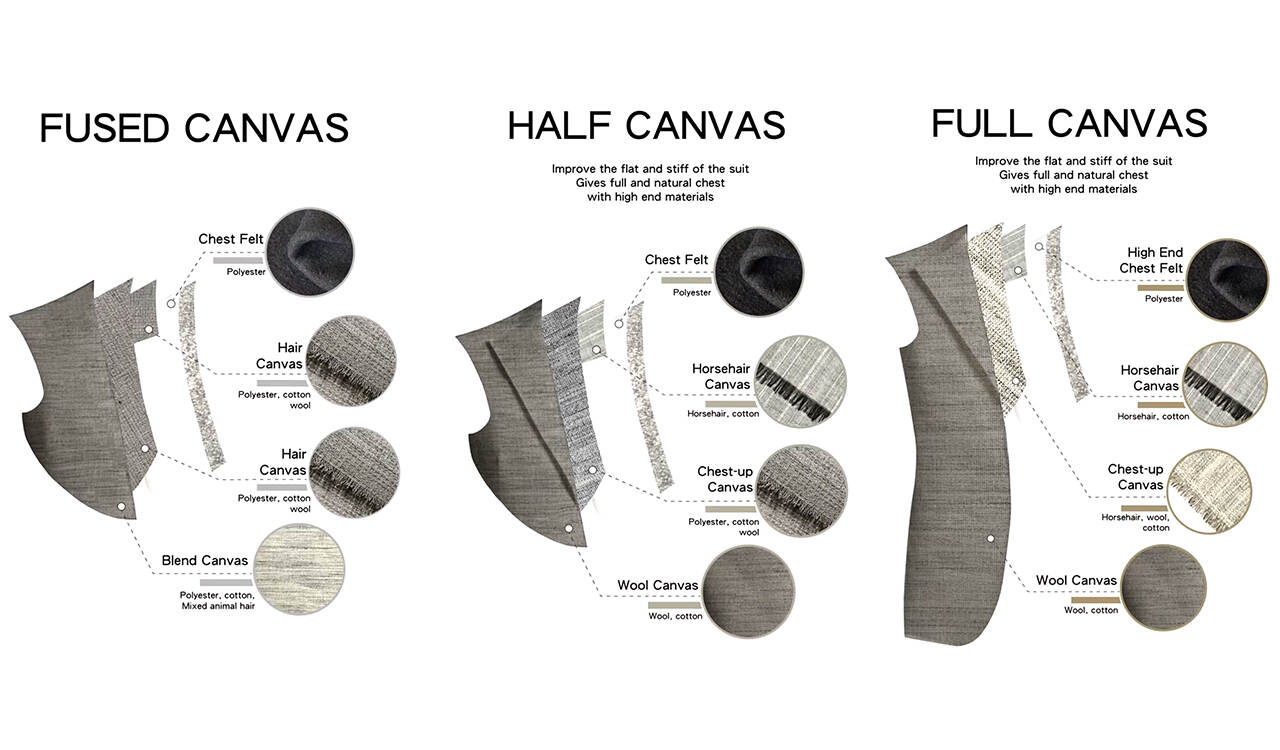

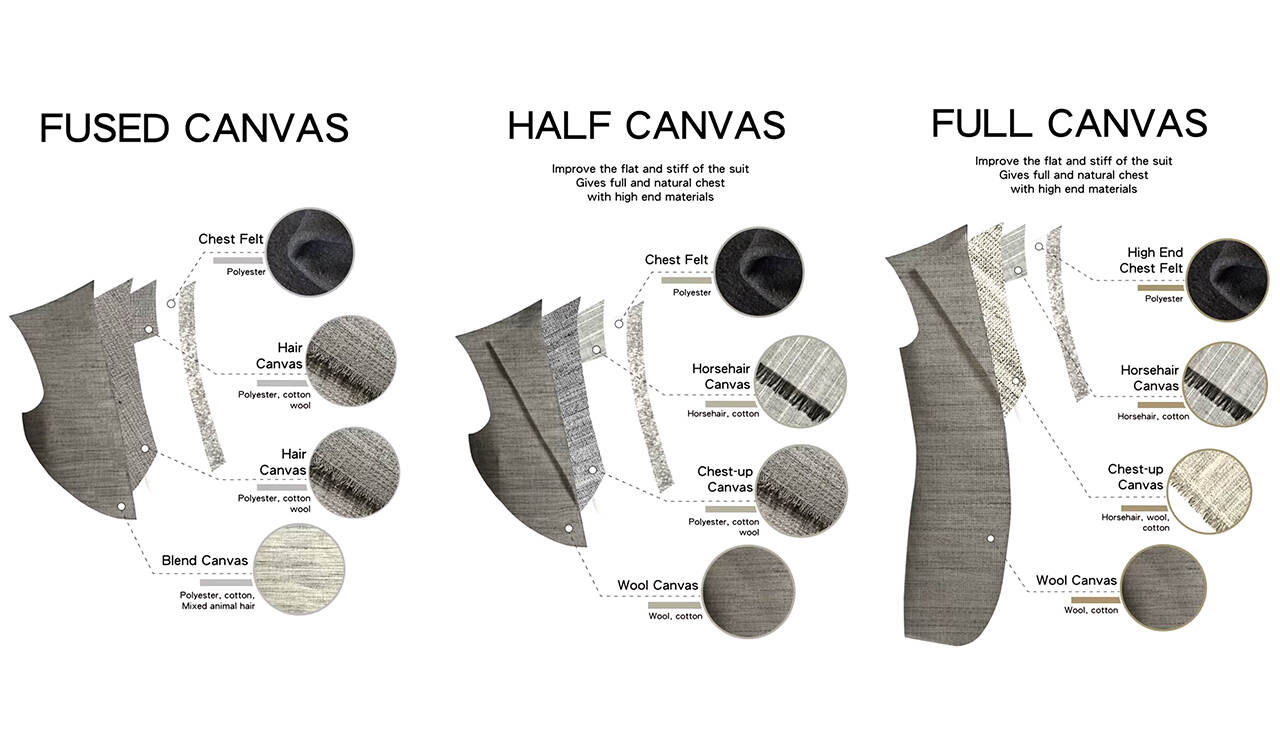

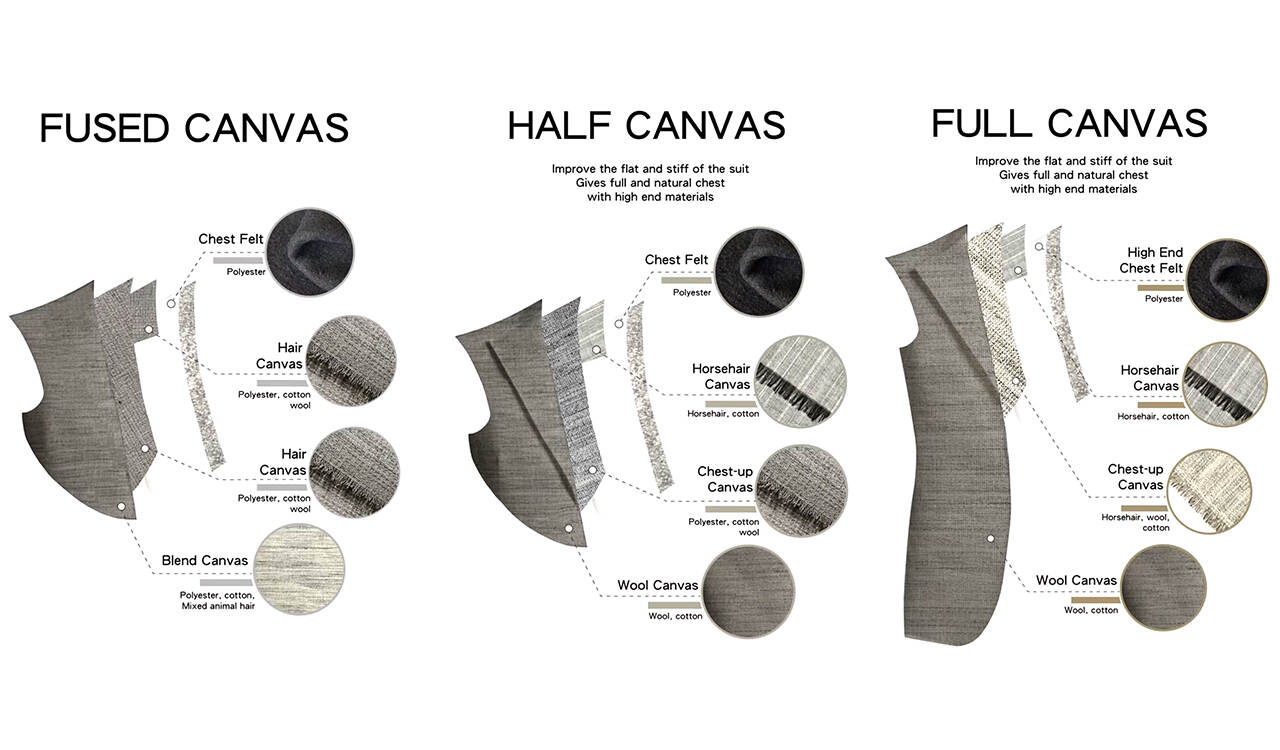

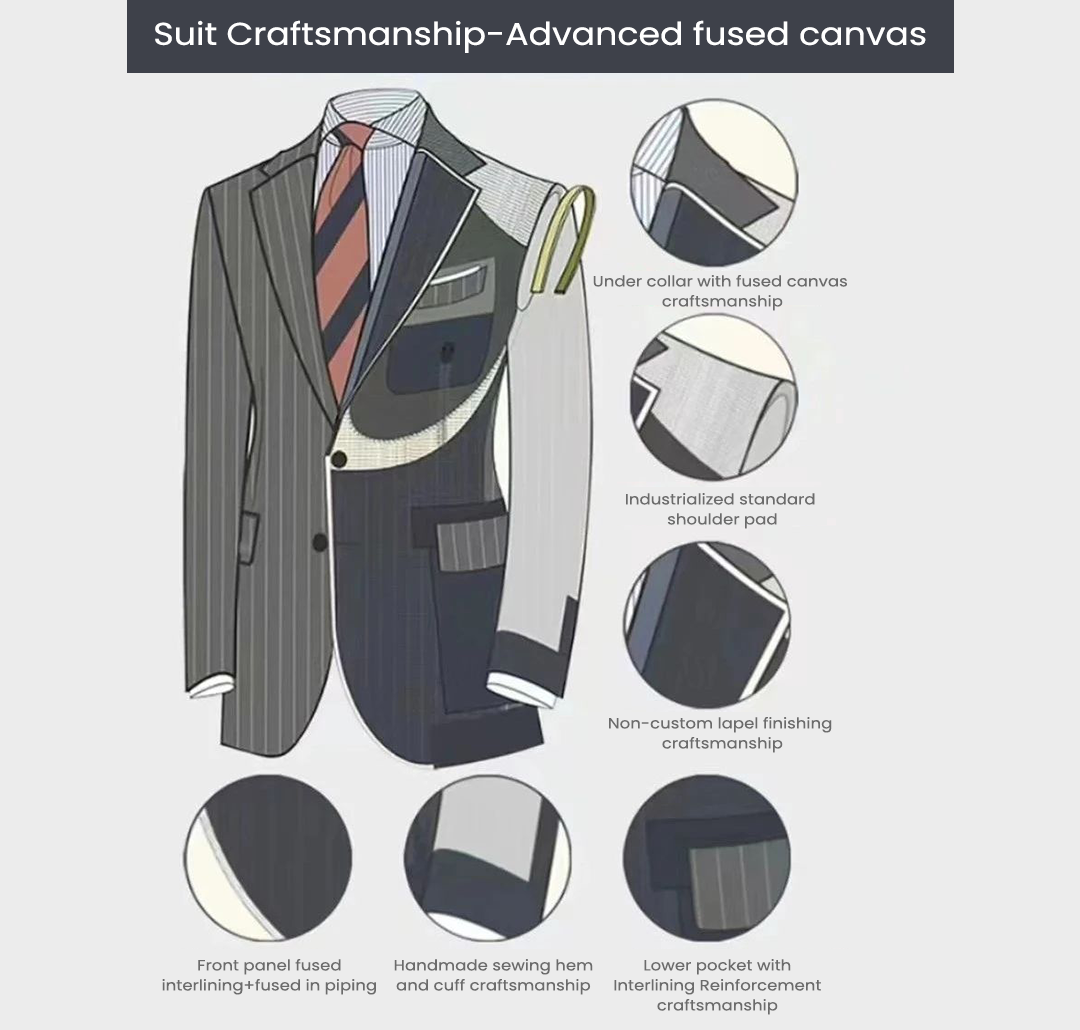

The fused canvas is made by sticking the interlining to the inside of the fabric by adhesive, with the addition of woven cotton and then sew and bond lining and fabric to make a jacket. Fused canvas is more structured than regular without interlining jacket, but interlining will make jackets less breathable and comfortable.

The fused canvas is suitable for some of the stiffer fabrics and will make the front panel a more structured look when it is made, which just happens to cater to the characteristics of polyester and viscose fabrics as well.

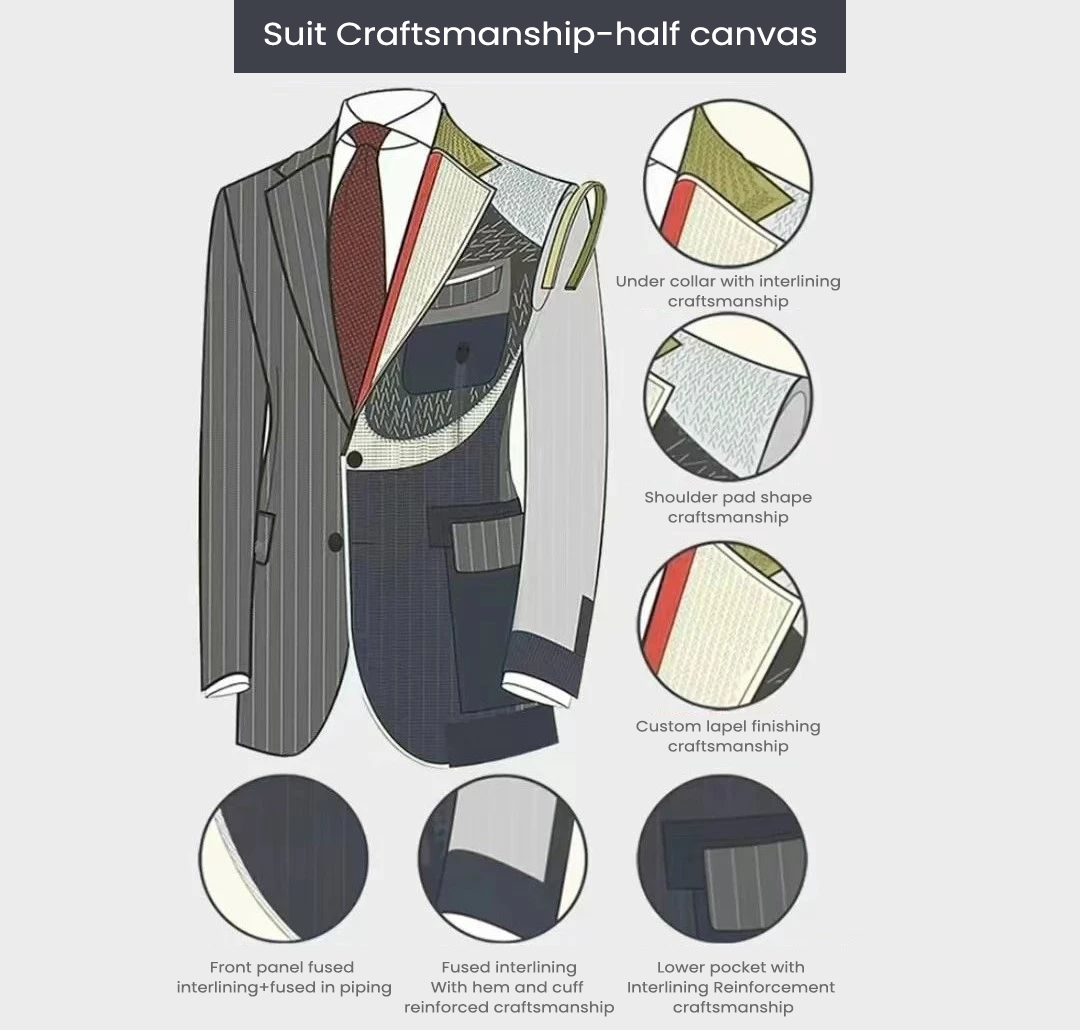

Half canvas is a half interlining sewn between the fabric and the lining, only above the stomach and not below. Half canvas is better than fused canvas. The increase of interlining makes the front chest more structured, and the arc of lapel is natural, stable and not easy to deform, so it can be used for a longer period of time.

However, below of stomach is a fused canvas. Below the stomach if not use interlining is only two pieces of fabric, obviously the upper part of the suit is not coordinated and the hem is too light, in order to visually maintain the overall coordination of the front piece of the fused interlining is not an indispensable part of the process of half canvas, and need to use interlining from the top to the bottom.

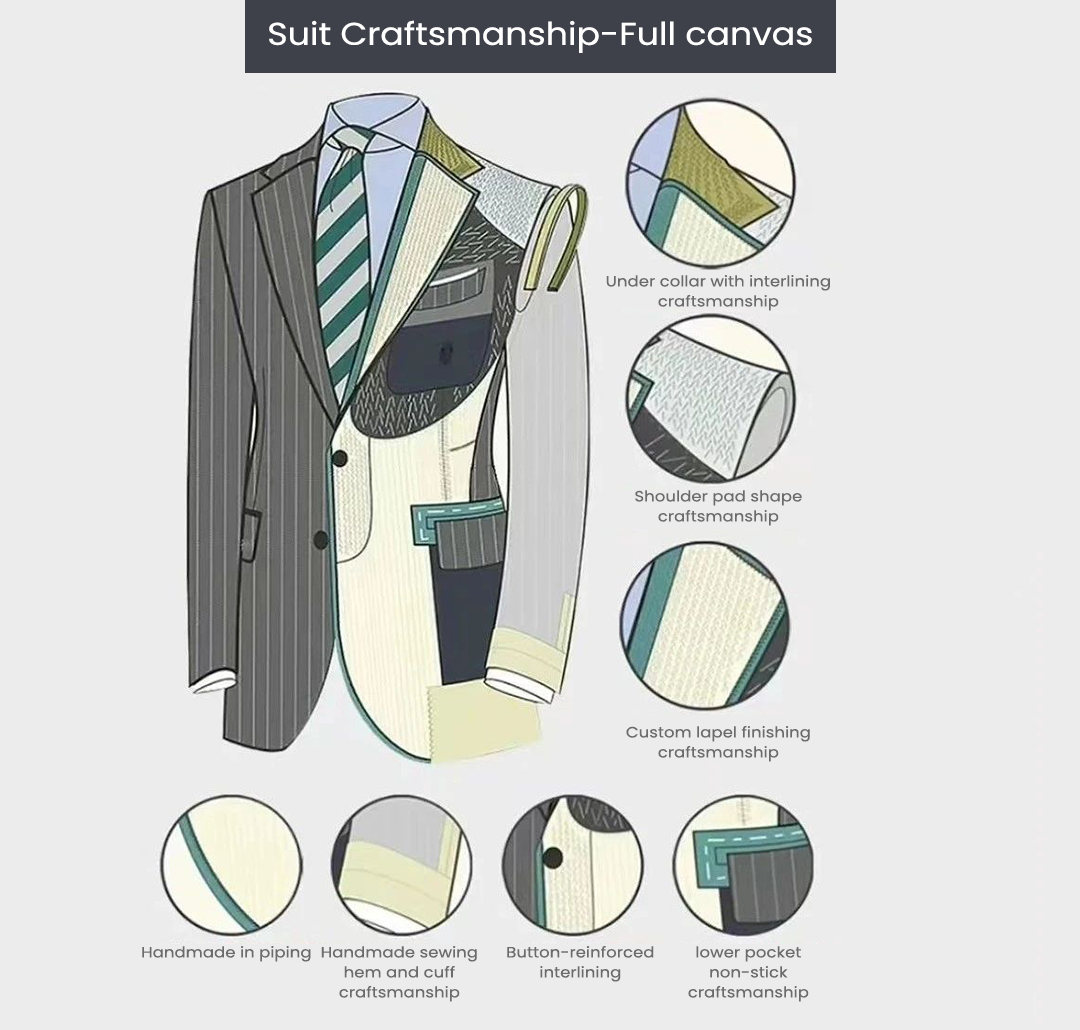

The biggest difference between full canvas and the above two canvas is not to use the interlining, because the interlining from the top sewing to the bottom can completely replace the woven interfacing, full canvas’ advantages, disadvantages, and difficulties in the production of the resulting.

Whether it is the level of breathability, drape, touch sensation, or gloss, the better the fabric, the better the final presentation of the jacket; if the fabric is poor, the final effect of the jacket followed down, so the full canvas is often used in high-grade fabrics. High-quality half canvas jackets save five years is not a problem, but full canvas jackets save more than ten years is also easy.